Automatic Paint Filling Machine

Automatic Paint Filling Machine

- Brand::

- Model::

Automatic Paint Filling Machine

Automatic Paint Filling Machine

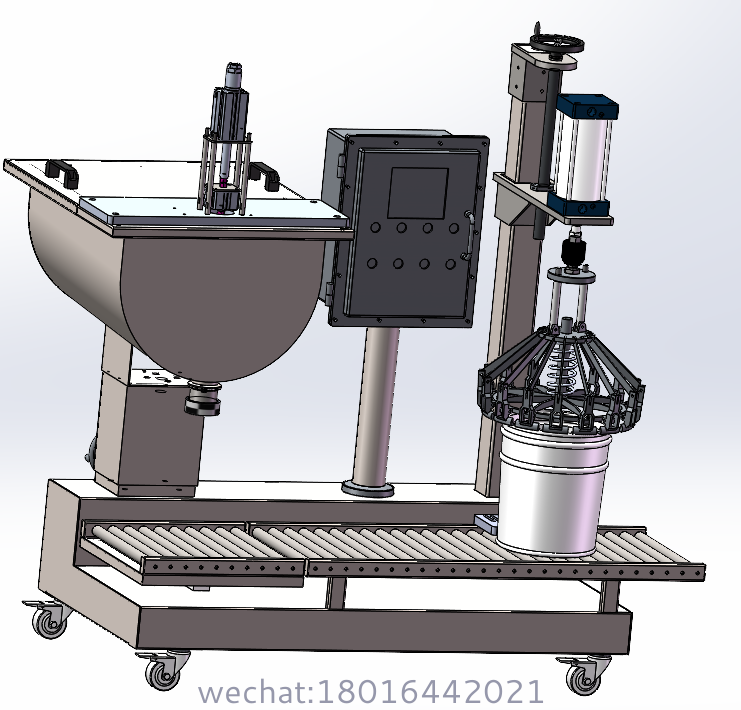

An automatic paint filling machine is a specialized piece of equipment designed to fill containers (such as cans, pails, or buckets) with paint or similar viscous liquids. These machines are widely used in the paint manufacturing industry to ensure accurate, efficient, and hygienic filling processes. They are capable of handling various types of paints, including water-based, solvent-based, and high-viscosity products like primers and coatings.

High Precision: Ensures accurate filling volumes, minimizing product waste and ensuring consistency.

Versatility: Can handle a wide range of paint types and container sizes.

Automation: Fully automated operation reduces manual labor and increases production efficiency.

Durability: Constructed with corrosion-resistant materials (e.g., stainless steel) to withstand harsh chemicals.

Ease of Cleaning: Designed for easy disassembly and cleaning to prevent cross-contamination.

Safety Features: Includes splash guards, emergency stop buttons, and overflow prevention mechanisms.

Customization: Can be tailored to specific production needs, such as filling speed, container size, and paint viscosity.

Gravimetric Filling Machines:

Fills containers based on weight.

Ideal for high-viscosity paints and precise filling requirements.

Uses load cells to measure the weight of the paint during filling.

Volumetric Filling Machines:

Fills containers based on volume.

Suitable for low to medium-viscosity paints.

Uses piston pumps, gear pumps, or peristaltic pumps to measure and dispense paint.

Piston Filling Machines:

Uses a piston mechanism to draw and dispense paint.

Ideal for thick, high-viscosity paints like primers and coatings.

Offers high accuracy and consistency.

Gear Pump Filling Machines:

Uses a gear pump to transfer paint from the storage tank to the container.

Suitable for medium-viscosity paints.

Provides smooth and consistent filling.

Filling Nozzle: Dispenses paint into the container. Can be designed for different viscosities and container sizes.

Pump System: Transfers paint from the storage tank to the filling nozzle. Options include piston pumps, gear pumps, or peristaltic pumps.

Conveyor System: Transports containers to and from the filling station.

Control Panel: Allows operators to set parameters such as fill volume, speed, and batch size.

Weighing System: Ensures accurate filling by weight (gravimetric filling) or volume (volumetric filling).

Safety Features: Includes splash guards, emergency stop buttons, and overflow prevention mechanisms.

Paint Manufacturing: Filling paint cans, pails, and buckets with various types of paint.

Coatings and Primers: Filling high-viscosity products like primers and industrial coatings.

Adhesives and Sealants: Filling containers with adhesives, sealants, and other viscous liquids.

Chemical Industry: Filling containers with solvents, resins, and other chemical products.

High Efficiency: Reduces filling time and increases production rates.

Precision: Ensures consistent fill levels, reducing product waste.

Hygiene: Minimizes contamination risks, especially in high-quality paint production.

Labor Savings: Reduces the need for manual labor, lowering operational costs.

Scalability: Can be integrated into larger production lines for fully automated operations.

When selecting an automatic paint filling machine, consider the following factors:

Paint Type: Ensure the machine is compatible with the viscosity and chemical properties of the paint.

Production Volume: Choose a machine that meets your production requirements (e.g., high-speed for large volumes).

Accuracy Requirements: Determine whether gravimetric or volumetric filling is needed.

Container Size: Ensure the machine can handle the size and type of containers you use.

Budget: Consider the initial investment and long-term operational costs.

Space and Integration: Consider the available space and whether the machine needs to integrate with other equipment (e.g., capping, labeling).

Krones AG

Accutek Packaging Equipment

Filamatic

Liquid Packaging Solutions

Bottling Solutions, Inc.

If you’re looking to purchase or customize an automatic paint filling machine, it’s important to consult with a reputable supplier to ensure the equipment meets your specific needs. Many manufacturers offer tailored solutions based on your production requirements and product characteristics.